Ferro Silicon Si65 Lump 10mm-100mm

Brand: Mingheng

Product origin: China

Delivery time: less than 100 tons (2-3 days)/1000 tons (within 30 days)

Supply capacity: Minimum 20 tons for ordering

1. Ferrosilicon can be used as deoxidize during steelmaking process.

2. Ferrosilicon 65 lump can make the process time faster.

3. Low consumption and cost for ferrosilicon 65.

4. Ferrosilicon 65 lump can promote the precipitation and spheroidization.

5. We provide cheap, low and reasonable price for all of our products.

Ferrosilicon is an iron alloy composed of iron and silicon. It is a ferrosilicon alloy made from coke, steel scraps, and quartz smelted in an electric furnace. It is a being widely used nowadays. As ferrosilicon 65 lump, it is composed of estimated 65% of silicon. The size of this ferrosilicon 65 is from 10mm up to 100mm. The ferrosilicon 65 lump 10mm-100mm is also an indispensable material for steelmaking. Silicon has important physical properties such as low electrical conductivity, poor thermal conductivity and strong magnetic permeability. Therefore, ferrosilicon can be used as alloying agent when smelting silicon steel (with silicon content of about 2 to 4%). Ferrosilicon 65 lump is ferroslicon that is crushed into certain proportion of small pieces and filtered through a certain number of screens. The size of this fesi 65 is from minimum 10mm to maximum 100mm. The fesi 65 lump 10mm-100mm is especially suitable for deoxidation requirements of continuous casting molten steel. It also has advantages of large specificity and strong penetrating power.

The most advantage of our products is that not only we strive to high quality standard production, but also we provide reasonable and cheap price for our customers. Our products have greatly high cost performance and cheap price compared with international and domestic markets. Low prices and outstanding products are two highlights that we serve for our customers continuously.

Ferrosilicon 65 lump can not only be used in the steelmaking industry, but also commonly used in the cast iron industry. The reason is that cast iron manufacturers can use ferrosilicon 65 lump instead of inoculants and nodlizers. It also has way cheaper price compares with steel and easier to be melted. The high-quality fesi 65 has excellent inoculation effect during iron casting which can promote the precipitation and spheroidization of graphite. It is a necessary material for the production of nodular cast iron.

-Advantages of ferrosilicon 65 lump 10mm-100mm:

1. Ferrosilicon 65 lump 10mm-100mm can effectively deoxidize during steelmaking process.

2. Ferrosilicon 65 lump 10mm-100mm can greatly reduce the process time of steelmaking deoxidation.

3. Ferrosilicon 65 lump 10mm-100mm can save the energy waste and cost expense.

4. Ferrosilicon 65 lump 10mm-100mm has the effect of promoting the precipitation and spheroidization of graphite in nodular cast iron production.

5. Reasonable, cheap price and high cost performance for all of our products.

-Uses of ferrosilicon 65 lump 10mm-100mm:

1. Cast iron manufacturers can use ferrosilicon 65 lump instead of inoculants and nodlizers.

2. Ferrosilicon 65 lump 10mm-100mm can effectively deoxidize during steelmaking process.

3. Fesi 65 10mm-100mm can be used as alloying agent when smelting silicon steel.

-How do we process packaging of ferrosilicon 65:

The fesi 65 should be packaged well before delivery. The requirements for ton-level packaging belts are pretty strict. Each bag is supposed be 1 ton or 1.25 ton and the packing material of ferrosilicon 65 lump should be plastic woven fabric. Because of ferrosilicon 65 will release hydrogen when it exposes to water or moisture, we must be careful not to load it beside the product with volatile moisture. Generally we can load ferrosilicon bags under 4 heights or 6 heights (each height is layer).

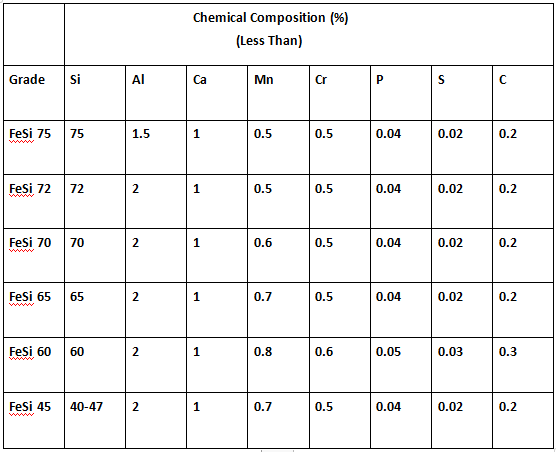

-Parameters of ferrosilicon:

Dandong Mingheng Trading Co., Ltd is located in Dandong City which is the largest border port in China. We have engaged in import and export business for more than 20 years. We mainly focus on the import, export and re-export for ferrosilicon, silicon carbide, silicon metal, tunsten concentrate, molybdenum concentrate, vanadium ore, ferromangnese, ferrochromium and other metal industries. Especially for our ferrosilicon products, we supply to countries all around the world with 45 ferrosilicon, 65 ferrosilicon, 72 ferrosilicon and 75 ferrosilicon that the average annual export volume is up to 30,000 tons. We have our own bonded processing zone in the Dandong Customs Bonded Warehouse that can produce according to customers' requirements. Our products have greatly high cost performance and cheap price compared with international and domestic markets. Low prices and outstanding products are two highlights that we serve for our customers continuously. Our products are exported to Japan, Korea, India, Turkey, Taiwan, Europe and other countries around the world. We are comprehensively praised by domestic and foreign partners about our products and customer service. We strive for survival by quality, development by high-standard products and integrated management. We are willing to cooperate sincerely with partners domestically and from other countries all around the world for mutual development.