Sic 88 Powder

Brand: Mingheng

Product origin: China

Delivery time: less than 100 tons (2-3 days)/1000 tons (within 30 days)

Supply capacity: Minimum 20 tons for ordering

1. The distribution for the size of sic 88 powder is concentrated and uniform.

2. We provide cheap, low and reasonable price for all of our products.

3. We produce high quality silicon carbide for the domestic and international markets.

4. The silicon carbide 88 powder has high thermal shock stability and load softening temperature.

5. Large specific surface area and clean appearance for sic 88 powder.

-Introduction of sic 88 powder:

Silicon carbide is an inorganic substance, it's chemical formula is SIC. It is made of high temperature smelted raw materials from the resistance furnace such as quartz sand, petroleum coke (or coal coke) and wood chips (salt is needed to in the production of green silicon carbide). Silicon carbide also exists in nature as a rare mineral (Moissanite).

Silicon carbide powder is the finely crushed silicon carbide. The components between silicon carbide and silicon carbide powder is same. As the sic 88 powder, it contains approximately 88% of silicon. The sic 88 powder has good self-sharpening, excellent grinding and polishing properties. It can be used for the cutting and precision grinding of crystals, the precision grinding of hard glass, the slicing of single crystal silicon and polycrystalline silicon rods. The silicon carbide 88 also can be used for the precision grinding of single crystal silicon wafers, the processing of superhard metals and soft metals such as copper and copper alloys.

The color of sic 88 powder is green. It is formed as crystal structure with high hardness, strong cutting ability, stable chemical properties and good thermal conductivity. The microscopic shape of sic 88 powder is hexagonal crystal. The Mohs hardness of sic 88 is 9.2. It’s Vickers microhardness is 3000-3300 kg/mm2. the Knoop hardness of silicon carbide 88 powder is 2670-2815 kg/mm and the microhardness is 3300 kg/mm3.

-Advantages of sic 88 powder:

1.We purchase high purity silicon carbide as the raw material to ensure the excellent cutting performance and stable physical state of the silicon carbide 88 powder.

2.The distribution for the size of sic 88 powder is concentrated and uniform.

3.The sic 88 powder has high thermal shock stability and load softening temperature that can ensure smaller linear expansion coefficient during load cutting. It can provide the stability for cutting and be well adapted to the cutting machine.

4.The surface of silicon carbide 88 powder is specially treated that has large specific surface area and clean appearance. It also has good compatibility with cutting fluids such as polyethylene glycol.

-Parameters of silicon carbide:

SIC(Min) | F.C (Max) | FE2O3(Max) | |

SIC 70 | 70% | 2.5% | 2.5% |

SIC 82 | 82% | 2.5% | 1.5% |

SIC 85 | 85% | 3.0% | 2.0% |

SIC 88 | 88% | 2.5% | 1.8% |

SIC 90 | 90% | 2.0% | 1.6% |

SIC 97 | 97% | 0.35% | 0.6% |

-Uses of silicon carbide sic 88 powder:

1.The sic 88 powder can dissolve in a basic oxygen furnace used for making steel, acts as a fuel.

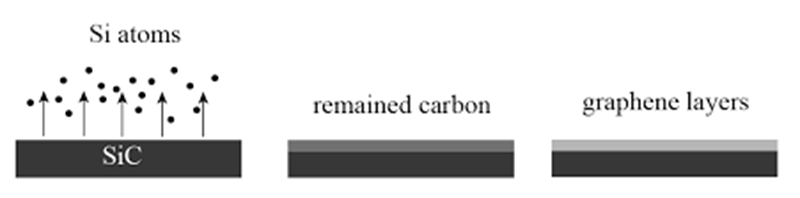

2.The sic 88 can be used in the production of graphene.

-Our packing and delivery attentions for your silicon carbide :

1. During transportation, silicon carbide should not be dragged with iron hooks. It should be prevented from being mixed with hard substances. It should not be strongly vibrated, rubbed, stepped or smashed. Throwing is strictly prohibited.

2. It should be stored in a cool and dry place so that we can prevent the inner and outside packaging bags from rupturing. We should also prevent moisture and other substances which may affect the using effect of silicon carbide.

3. Water immersion is strictly prohibited. The reason is that the silicon carbide is a high-grade abrasive, it must be absolutely prevented from water immersion during transportation, storage and use.

Dandong Mingheng Trading Co., Ltd is located in Dandong City which is the largest border port in China. We have engaged in import and export business for more than 20 years. We mainly focus on the import, export and re-export for ferrosilicon, silicon carbide, silicon metal, tunsten concentrate, molybdenum concentrate, vanadium ore, ferromangnese, ferrochromium and other metal industries. Especially for our ferrosilicon products, we supply to countries all around the world with 45 ferrosilicon, 65 ferrosilicon, 72 ferrosilicon and 75 ferrosilicon that the average annual export volume is up to 30,000 tons. We have our own bonded processing zone in the Dandong Customs Bonded Warehouse that can produce according to customers' requirements. Our products have greatly high cost performance and cheap price compared with international and domestic markets. Low prices and outstanding products are two highlights that we serve for our customers continuously. Our products are exported to Japan, Korea, India, Turkey, Taiwan, Europe and other countries around the world. We are comprehensively praised by domestic and foreign partners about our products and customer service. We strive for survival by quality, development by high-standard products and integrated management. We are willing to cooperate sincerely with partners domestically and from other countries all around the world for mutual development.